blister sealing test|rubber blister testing kit : company Selection: Based on earlier R&D and validation. Goal: Prevent or ID/remove defects of greatest concern. CCI Testing: 100% nondestructive CCI tests, or Sampled product CCI tests. Seal . Participe de promoções de passaportes, ingressos e shows n.

{plog:ftitle_list}

Resultado da Enviar una solicitud. ¡Estamos aquí para ayudaros, ya sea algo técnico o sobre comportamiento! ¡Envía una solicitud! A menos que se pierda en un portal, no tardaremos en ponernos en contacto contigo. Detalles. 1. Elige un tipo de solicitud -.

testing for blister packaging

compression tester autozone loan a tool

rubber blister testing kit

Testing Methods for Blister Package - Leak, Permeability, Seal Strength, Impact Resistance. Pharmaceutical blister packaging, also called PTP (press through packaging), is one of the main forms of pharmaceutical packaging. It’s suitable for the mechanized packaging for solid .Tensile Strength Testers. Labthink tensile strength testers are featured by easy-to .There are two basic types of seal strength testing addressed in ISO-11607: tensile strength testing and burst or creep (inflation) testing. Tensile seal strength testing (ASTM F88) uses a .

Suitably sized defects in the laminate, tray material, and seal can be detected using this test method. The sensitivity of this test method depends upon a range of factors .Selection: Based on earlier R&D and validation. Goal: Prevent or ID/remove defects of greatest concern. CCI Testing: 100% nondestructive CCI tests, or Sampled product CCI tests. Seal . Standard operating procedure to determine the leak in strip and blister by leak test using leak test apparatus.

When it comes to blister packs, CCIT involves specialised testing techniques to identify defects in the blister packs to prevent contamination and moisture ingress. These defects may arise from issues like faulty seals, cavity defects, material . Knowing the blister sealing materials, the tools you are working with, and maintaining a good knurl are just a few of the steps to the perfect blister seal.

compression tester calibration

First, design blister cards that minimize film and foil requirements, yet achieve the requirements for seal area and product protection. Next and where possible, replace pneumatic cylinders with electric (servo) cylinders to .The peel test kit is designed to test the sealed seams of packaging by peeling the lid or sealing material from dimensionally stable or rigid packaging. It has a variable gripping unit to fix the blister packaging. During the test, up to 90% of . packages, and heat seal strength is an important testing item for sealing performance. As to blister packages, both in the testing for aluminum foil and PVC sheet, or aluminum foil and PVC/PVDC laminated sheet, heat seal . YBB00292004, Test Method for Thermal Tensile Ratio. Cut two square pieces, with each side of 120mm±1mm, from the sheet . The frequency for leak seal test – Leak Test Apparatus: Leak seal test shall be performed at the start of operation and at an hourly interval during the stripping operation. In the case of Blister, Bottle filling and Sachet Leak .

•Blister packaging Seal Quality Tests 28. H. Wolf, D. Guazzo, ASTM Standard Test Method for Nondestructive Airborne Ultrasound . Seal Integrity Test for Flexible Packages, ASTM F02 Committee meeting, April 18, 2007 Seal Quality Tests 29. H. Wolf, D. Guazzo, ASTM Standard Test Method for Nondestructive Airborne UltrasoundThe Sepha PakScan is a non-destructive test method. The machine performs a dry seal integrity test enabling manufactures to recover packs that have passed the leak test and return them to the production line. The system can identify gross holes, leaks and weak seals down to 10μm* in up to 10 packs simultaneously within 30 seconds.Blister Sealing & Packaging. With Visual Pak’s high-volume blister assembly and sealing processes, our production teams can seamlessly manage multiple or single pack designs for low and high-volume programs. Whether your project calls for blister-to-card or blister-to-blister packaging, our blister sealing capabilities offer you maximum .

Learn 8 Blister Sealing top tips and discover how to avoid blister seal issues. Read more on achieving and maintaining an excellent blister seal. [email protected] 616-888-9081 +44 (0)28 9048 4848 . New video – How do you test for leaks in blister packaging?

The Process of Heat Sealing Blister Packs. To seal a variety of blister packs, the blister packaging machine has to be set to various custom settings, like the heat level, pressure, and dwell time. Each step of the heat-sealing blister packaging process impacts the strength of the package — especially the settings during the final heat sealing.

Sustainable packaging alternatives, lower cost packaging, and variations in production line sealing parameters are frequently assessed with seal integrity tests. With the renewed interest in sustainable packaging, alternate structures such as monolayer recyclable flexible packaging are being explored, so ensuring that the seals for these .

Following are the issues that are encountered during the blister packing process: Leak test failure; Wrinkle on Blister; Cavities Defects; Blister Cavity stuck in forming Plate . Pinhole detector not working Probable causes: Homing not done; Blister Damage in sealing station; Motor overload; Emergency machine stop; Blister-dropping problem .

Testing blister packaging-Blister packs are tested for perfect sealing with the following steps: The blister strips are first placed in a desiccator and a vacuum is applied, The vacuum is then released and blisters are removed. Humidity in the air sticks as moisture on the strips when a vacuum is applied, the moisture is wiped off with paper .Machines or manual dies meticulously shape the card, creating spaces for the product and the blister. Whether it’s a rounded edge, a unique silhouette, or intricate designs, die-cutting tailors the blister card to perfection. Sealing: The culmination of the blister packaging process lies in sealing. The product is placed between the blister .The Sepha VisionScan 3D is a blister leak test solution that takes non-destructive leak testing to a new level. The next generation machine is built around our new 3D measurement technique to test the integrity of pharmaceutical blister packs. . Build leak tests into Quality Assurance procedures for your blister packaging line. Objective seal .The heat-seal coating should be capable of forming an adequate seal with the blister film to which it is intended to seal. The materials used in the makeup of the heat-seal layer meet 21 CFR 175 and 177. . Suppliers of these materials typically provide quantitative data, obtained from well-established test methods, to highlight the protective .

How to achieve a brilliant blister seal. Most pharmaceutical companies around the world rely on blister packs to guarantee the uniformity, purity, integrity, safety and stability of their products. But these criteria will only be met if the blister seal remains intact throughout the product’s shelf life.

Seal Peel Test – Failure issues. Burst / Creep Test. Burst Test - ASTM F1140. Determines package seal strength. Test system pressure is pre-set to a point above the known burst point. Perform by pressurizing the package until it bursts. Whole package. Porous or non-porous.Test Methods, Application Introduction • Terms and definitions • Maximum Allowable Leak Limit (MALL) • Inherent package integrity • Package integrity profile. . Form-fill-seal plastic or glass ampules Syringes or cartridges Flexible bags or pouches. Packages for some drug/device combination products (e.g., autoinjectors) Watch how to perform a 180-degree peel test on syringe blister packs and get a tip on how to easily fasten small tabs to the grips. In this video, we use the.

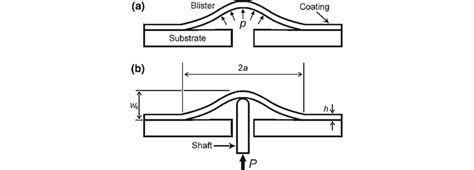

This is why cold form blisters are most suitable, to investigate sealed seam quality. Considering a faultless sealed seam, the total permeability (Q total) is the sum of the permeabilities of the single layers (Q sealing medium + Q heat seal lacquer).For similar permeability coefficients the heat seal lacquer (thickness approximately 5–9 μm) should have .200 River's Edge Drive, Medford, MA 02155 i-Leaktek 6600 Leak and Seal Strength Tester—Medical Blister Test i-Leaktek 6600 Leak and Seal Strength Tester is designed for determination of seal strength and seal performance test of various heat sealed flexible package and sterilized package, seal performance test of pilfer-proof closures, quantitative testing of .

heat seal strength. 4. Thermal Tensile Ratio Testing Thermal tensile ratio is the important testing item for PVC sheet or PVC/PVDC laminated sheet; it’s defined as the size changes after enduring a certain temperature within a certain period of time, and is the ratio of the spot distance variation and the initial spot distance in percentage.

Other pitfall prevention methods include: communicating tooling requirements with the tooling manufacturer to ensure adequate seal area between the cavity and the blister card edge (or perforations between sections); determining what sealing temperatures and pressures need to be during the Operational Qualification testing; and testing .

The Sepha EZ blister can form, seal, perforate, and cut your syringe packaging seamlessly and efficiently. Cold-form material provides an impenetrable barrier that prevents moisture, light, oxygen, and other gases from passing through the syringe packaging, improving product shelf life and integrity. That’s why the Sepha EZ blister is .

AMI Seal Integrity Test System: Blisters, Vials, Bottles. Source: . the products can be sampled directly from the production line and loaded in the test chamber without any specific conditioning. At the end of the test sequence, the result is clearly displayed and a PDF report is automatically generated at the batch closure. . leak testing .A blister pack for pills or capsules is typically made up of pre-formed plastic, an aluminum, or plastic seal. Blister integrity testing assesses the function and durability of this packaging system, including its ability to protect the drug product and the process of .The level of insulation a drug needs from the destabilizing factors can only be known with a tough stability test done with different blister sealing methods, machines and environments to match the humid and sunny conditions in economies like India, China, and Latin countries. So, if you’re supplying regular medication for seasonal illnesses .

Title: Standard operating procedure of Blister Sealing test for tablet strips. 1.0 OBJECTIVE:. To lay down a procedure of Blister Sealing test for strips/blister packing. 2.0 SCOPE:. This SOP shall be applicable to Q.C Dept. 3.0 RESPONSIBILITY:. 3.1 Doing: Q.C Analyst.. 3.2 Checking: Q.C-Manager.Sealing Temperature. The heat sealing process, as previously described, marries two materials and creates a bond. To achieve this bond, one of the materials typically carries a surface sealant layer. The heating elements of heat seal packaging equipment are raised to a temperature high enough to either melt or activate the sealant.

Resultado da Antes de comprar na Qualidoc, verifique se o site é confiável. Nós testamos, abra e descubra. Verificar novo site. Resultado da verificação do site qualidoc.com.br. Qualidoc Farmácia Digital LTDA. CNPJ: 21.659.253/0001-41 Informação coletada através do Whois do Registro.br. Acesse para ver .

blister sealing test|rubber blister testing kit